The CHIPS and Science Act was passed a year ago with great fanfare in Washington.

Arizona and other locations around the county celebrated as well, since there would soon be federal money priming the pump for private investments in new semiconductor factories. Multi Circuit Board

Thousands of high-tech jobs have already come to the state, and more are on the way.

While the CHIPS Act was a great first step in restoring a balanced and resilient supply chain for semiconductors, it falls short when you look at the entire microelectronics ecosystem.

We depend almost entirely on Asia for the components that semiconductors need to function.

The COVID-19 pandemic was a wakeup call for manufacturers of everything from F-150s to F-35s. Consumers and lawmakers learned that we don’t make enough chips to support American-made products.

Congress rang the alarm bell and created the CHIPS Act based on the fact we make only 12% of the world’s supply of semiconductors. This makes us vulnerable to supply chain disruptions caused by either political decisions or natural disasters in distant countries.

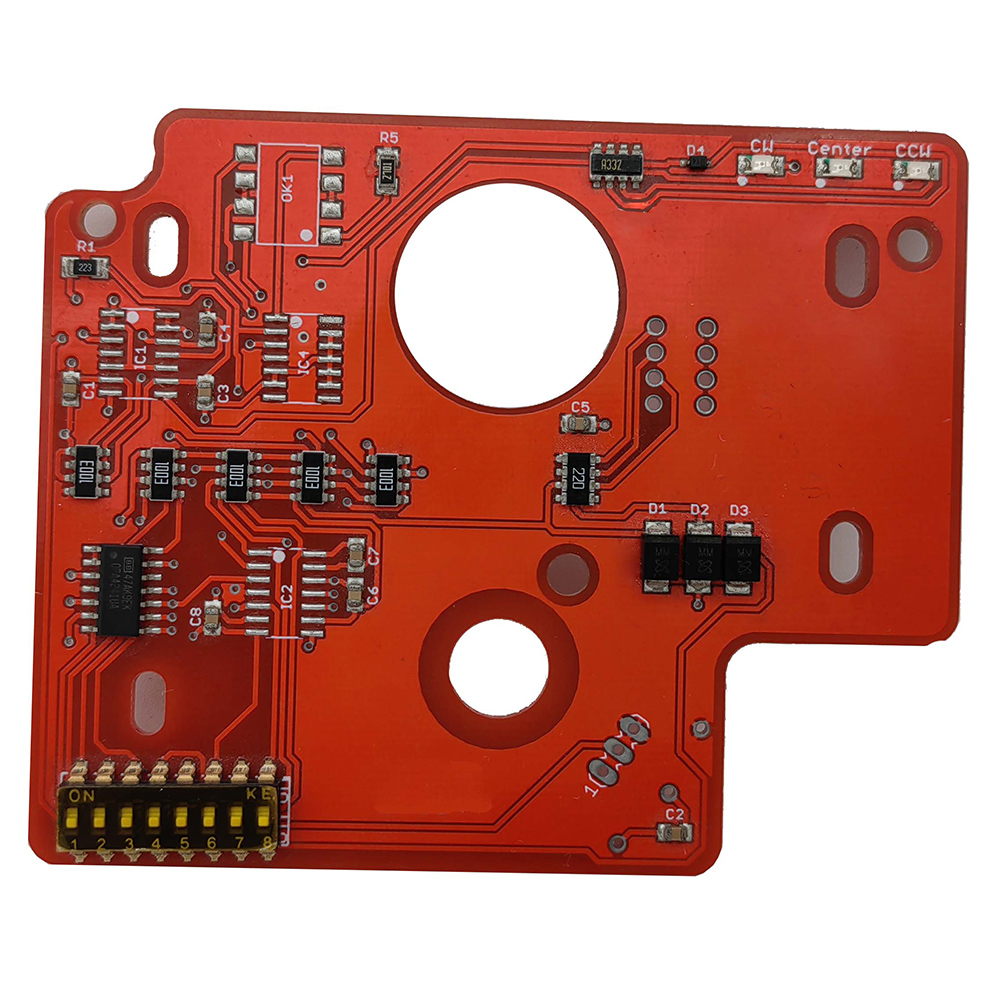

The situation with printed circuit boards, or “PCBs,” is even more dire.

Even though America invented and led the world in PCB technology, our PCB market has shrunk from 30% to 4% of the world’s supply over the past 30 years.

Often mistaken for simple green pieces of plastic, PCBs are in fact complex and precisely engineered, forming the central nervous system that enables the semiconductor “brain” to control the function of any electronic system.

Many necessities in modern life, from air conditioners to defense and space systems, could not function without PCBs.

We may not worry about the source of the chips and PCBs in our toasters or microwave ovens, but we must have secure and trusted sources embedded in critical infrastructure like telecommunications, banking, medical and national security systems.

The CHIPS Act created funding and attracted investment for chips, but without concurrent support for increased domestic sources of PCBs, most of those new Made In America chips will be shipped across the world for advanced packaging with foreign-made PCBs.

We don’t solve the supply chain problem by only addressing part of the ecosystem.

Rogers Corporation has been producing high performance PCB materials in Chandler for 55 years, for use in applications such as electric vehicles, defense and space systems.

Chip industry needs workers:Can Arizona meet demand?

Nearby Isola Group’s newly automated factory produces highly specialized materials used in PCBs and other high-consequence electronic components.

The hundreds of dedicated employees on the local production lines understand the importance of PCBs and the materials that make them possible.

Despite the commitment of companies like Rogers and Isola, the U.S. simply does not produce enough PCBs and base materials to create a secure, trusted and resilient domestic supply chain.

We are too dependent on distant countries for PCBs and other materials that power the electronics that run our country.

We appreciate what Congress did in the CHIPS Act to provide the initial investment that in turn attracted private investment for the semiconductor industry. It means jobs and prosperity for Arizona.

But without similar action, the country’s continued dependence on other nations puts at risk an uninterrupted supply of trusted and secure PCBs and the critical materials they are made of.

To nurture and grow the entire microelectronics ecosystem we call on Congress to pass H.R. 3249, the Protecting Circuit Boards and Substrates (PCBS) Act.

The PCBS Act calls for a 25% tax credit for companies buying American made PCBs, along with a $3 billion investment in related research and development, physical plants and workforce development.

It’s time to finish the work that the CHIPS Act started and level the playing field for American companies.

The PCBS Act will help achieve our national goal of a secure, trusted and resilient national microelectronic supply chain: our national and economic security depend on it.

Pcbs Electronics Roger Tushingham is vice president and general manager of Radio Frequency Solutions at Rogers Corporation. He resides in Scottsdale. Travis Kelly is chairman of the Printed Circuit Board Association of America and CEO of Isola Group in Chandler. Reach them atRoger.Tushingham@rogerscorporation.com andtravis.kelly@isola-group.com.